At Metal Hero we specialise in supplying the multiple industries with metal fabrication machinery.

We build machines tailored for your individual needs as well as provide off-the-shelf solutions for common application. We are experts in supporting all your cutting, bending and welding needs!

Numerically controlled fiber laser cutters by Metal Hero are cutting-edge machines designed for modern businesses to accurately and efficiently cut any shape from sheets of stainless steel, carbon steel, aluminum, copper, titanium, or to perform rotary machining on pipes and profiles. There’s no doubt that achieving precise cuts without the need for additional finishing or deburring significantly accelerates mass production. By using Metal Hero’s fiber laser systems, you’ll experience a new level of cutting precision. You’ll be able to cut intricate parts, round or rectangular profiles, and achieve a flawless, smooth cutting surface without burrs.

Fiber laser cutters built by Metal Hero are tailored for each application. The configuration choices include adjustments to the working area, the laser source power, the source manufacturer, extraction systems, and compatible optional equipment for process automation.

PROFESSIONAL CONTROLS

The machine is built for continuous industrial use and comes equipped with an intuitive, user-friendly control system. It features a dedicated operator panel that ensures stable and precise guidance of the laser beam. For those who value mobility, the machine is also equipped with a tasker.

HIGH-QUALITY LASER FIBER GENERATOR

The Metal Hero fiber laser cutter uses only trusted fiber laser sources and cutting heads from well-known manufacturers. The fiber laser source is designed to minimize laser beam deflection while offering excellent thermal and electro-optical performance, resulting in a smooth and precise cutting surface. The high quality of the laser beam generator, combined with an industrial liquid cooler, ensures a service life of at least 100,000 hours. We offer sources with power ranging from 300 W to 12,000 W, carefully selected based on the specific application.

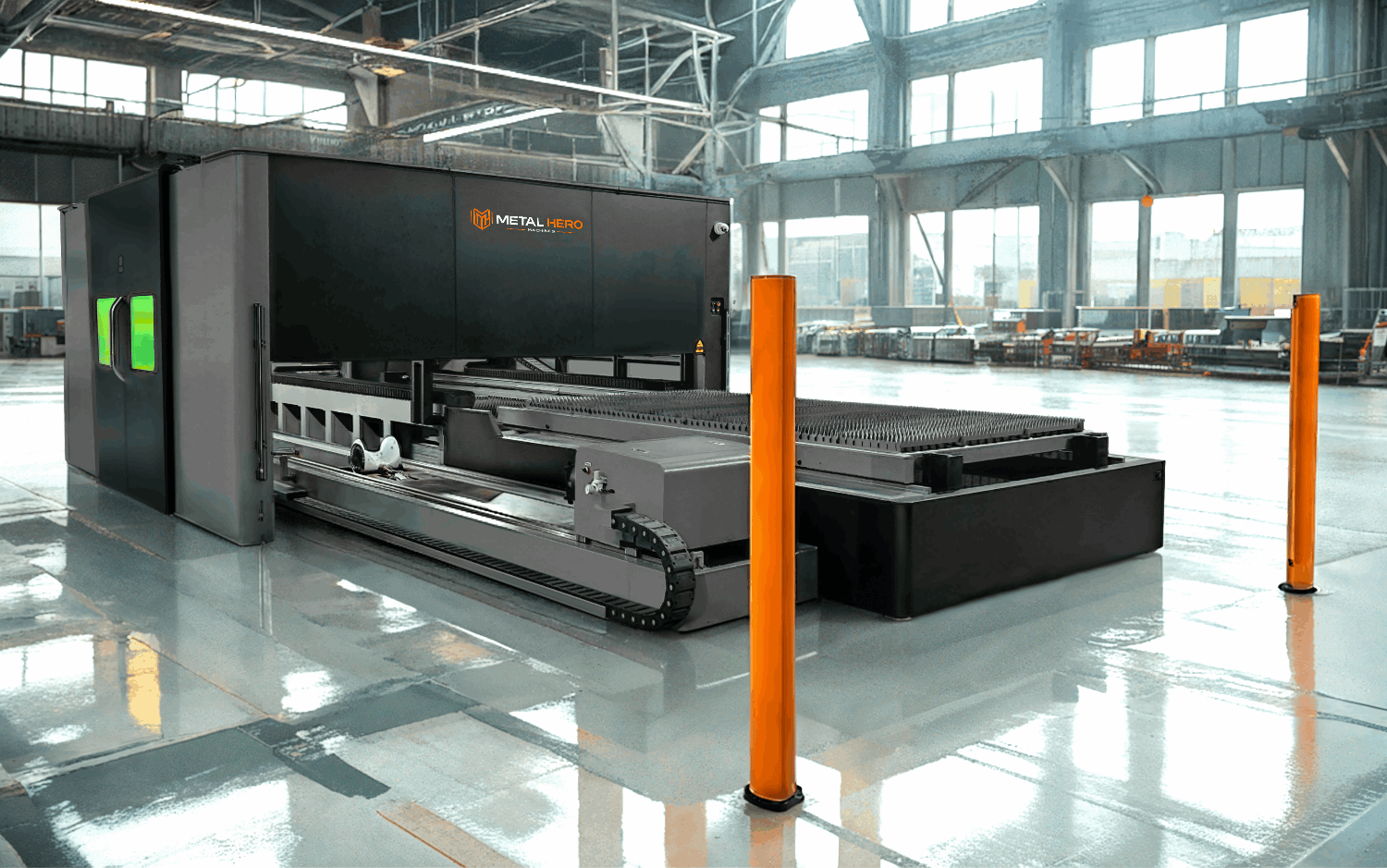

CONSTRUCTION AND HOUSING

The device features a stable subframe structure and reinforced frame, effectively minimizing vibrations and deformations during the cutting process. Metal Hero cutters are available in two configurations: an open-frame design or a fully enclosed plotter with a complete work field cover. The full enclosure is specifically designed to protect the operator from the high-power laser beam, reduce noise, and minimize the impact of environmental factors (such as temperature, pressure, and humidity) on the cutting process. It also helps improve the precision of the laser beam guidance. To enhance safety, the system is equipped with safety gates or light curtains.

DYNAMICS AND HIGH CUTTING SPEEDS

The motion system, which includes a robust frame and a cutting head height compensation mechanism, is designed to deliver dynamic movements and achieve high speeds. The frame is driven from both sides to ensure precise motion control. The type of drive system is chosen based on the customer’s specific requirements. The motion ranges in both the X and Y axes are equipped with stops and flexible pressure pads. Transmission components, such as gears and guide systems, are sourced from the world’s leading manufacturers. Working comfort is further enhanced by features like autofocus and an automatic nozzle cleaning system.

PRODUCTIVITY

The Metal Hero fiber laser cutter with numerical control enables the cutting of any designed part—whether with simple or complex contours—in a short time, delivering exceptional quality and precision. Customers can choose a machine with a rotary attachment for cutting pipes and profiles, or opt for a machine specifically dedicated to pipe and profile machining, including a head for processing irregularly shaped profiles.

WHICH FIBER CUTTER SHOULD YOU CHOOSE?

As experienced suppliers of fiber cutters, Metal Hero helps customers answer these questions and advises on the specific machine parameters that will meet their needs. Equally important is choosing the right supplier who can provide expert support in critical situations. A reliable machine manufacturer who understands the machine’s design, operation, and maintenance can significantly reduce the risk of downtime due to equipment failures. This minimizes the chances of experiencing delays, as the supplier will have the expertise to resolve issues quickly.

Anyone considering a fiber laser cutter faces the same key questions. The most important step is to answer the following:

What thickness of materials will be cut, and what is the smallest hole size required?

Will there be a focus on increasing production efficiency and automating the process, or is the goal to handle low-volume, custom orders?

Will 3D machining be needed?

Does the supplier have a proven track record in providing machinery, along with technical support and a spare parts inventory?

What materials and what sizes will be processed most frequently?

WHY CHOOSE METAL HERO?

At Metal Hero, we pride ourselves on offering the highest level of sales and after-sales service. We invite you to visit our headquarters in Łomianki to see and test the machines in our dedicated demonstration area.

Buy with Confidence!

With extensive knowledge and years of experience, backed by hundreds of testimonials from satisfied customers, we ensure a risk-free purchase. Our website features a vast database of customer references, making us one of the most trusted suppliers in Europe!

Comprehensive Technical Support:

Our large, qualified technical support team is responsible for machine implementations, training, and both warranty and post-warranty services. Support is available in both Polish and English, ensuring clear communication no matter the need.

Fast Service Response:

Thanks to our in-depth understanding of the machines we build, we offer fast service responses and quick resolution of service orders. We also maintain a warehouse stocked with the most commonly used spare parts ensuring minimal downtime.

Quality Components and Software:

We use only tested components and control software sourced from reputable manufacturers. As an official distributor for many leading brands, we guarantee high-quality products built to last.

Optimized for Universal Applications:

For versatile applications, our cutting machines can be equipped with a sheet storage unit for automatic loading, perfect for industrial environments aiming to streamline production and save valuable time.

One Supplier, One Service Provider:

We offer CNC machines across multiple technologies, meaning you can rely on one supplier and service provider for all your needs. This ensures faster operations and minimizes production downtime.